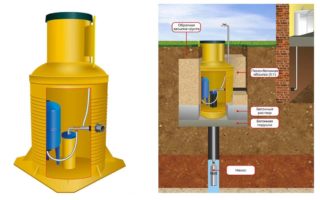

A caisson for a water well is a special chamber for the mouth of a hydraulic structure at a level below the earth's surface. It is installed above the water intake shaft in order to achieve the most comfortable access, and for the subsequent installation of autonomous water supply equipment.

Functions and purpose

During the cold winter period, well operation becomes more difficult. During frosts, water lifted from the depth freezes and spoils or ruptures pumping equipment. For normal operation of the well, the owner needs to make sure that its head is warm. Using a caisson, you can create such conditions.

The device of a standard caisson for a well is straightforward. This is a container that does not allow water drains to pass through. It is placed in the ground and attached to the casing. Thermal insulation will protect the borehole shaft from the cold.

The caisson is used to install pressure equipment. In it, it is closed not only from underground waters, but also from insects and rodents.

Inside the structure, you can place all the devices necessary for using the well:

- reverse osmosis treatment and filtration systems;

- pumping unit;

- pipes and valves, including those with electric and pneumatic drives;

- automatic control unit.

There are technical openings in the side walls for conducting electric wires and water mains.

Caissons are round or rectangular in shape. The first section must be at least a meter, otherwise a person will hardly fit inside the caisson. Sizes are calculated according to needs. An unnecessarily small structure will be inconvenient for the installation of equipment and repair work. The oversized structure is too expensive.

Without a caisson tank, well exits are equipped only in warm rooms. Additionally, you need to install a downhole adapter - a compact adapter mounted in a casing string. It is easier to equip it than a caisson, but further prevention and inspection of the well will be more difficult.

Types and designs

Caissons are made from reinforced concrete and reinforced concrete rings, brick, plastic, metal and polymer sand mixture. The performance is largely dependent on the material used to manufacture the sealed chamber.

Reinforced concrete structure

The caisson made of reinforced material or reinforced concrete rings for the well is strong and durable. The first option involves making a structure with your own hands. A base is being prepared, on which the iron reinforcement for the walls is mounted, and then pouring takes place. In the second case, concrete rings made at the factory are laid on the equipped base, and a slab with a cover is installed on top.

What is good about a concrete caisson:

- durable and strong;

- resistant to mechanical stress and soil movement;

- weighs a lot.

The latter indicator does not allow the caisson to float during the rise in the level of subsoil waters, and therefore the structure does not require additional fastening in the ground during installation.

Large weight is both an advantage and a disadvantage of a structure. Mounting rings is not feasible without the use of special equipment, transportation is also associated with difficulties.

Also, concrete absorbs moisture that penetrates into the caisson and destroys its walls. In order for the structure to serve longer, it is necessary to waterproof it with high quality.

The disadvantage of a concrete caisson is poor thermal insulation. To create a suitable temperature for the operation of the equipment, you need to insulate the chamber.

Brick building

The brick caisson has similar advantages and disadvantages. It will take much longer to build, but during construction you can use broken and used material.

The advantages of brick structures include:

- high reliability and durability;

- relatively low thermal conductivity;

- profitability.

For the price, a brick caisson, especially if it is made of used material, is cheaper than all other options.

The disadvantages also include the ability of the material to absorb moisture, which leads to the need for waterproofing.

Metal product

It is a large metal box with threaded bushings welded into the walls for laying communication lines. It is made of sheet metal, with a thickness of 3-4 mm, better than steel. Aluminum caissons are less durable but less expensive.

By design, the metal caisson is simple, reliable, sealed and durable. The flexibility of the metal prevents cracks from appearing in the structure. You need a mandatory high-quality insulation.

A heavy metal structure is resistant to earth swelling. Does not require additional fixation during installation. But also with the installation due to the severity of the container, you will have to tinker. The disadvantages also include susceptibility to corrosion and high thermal conductivity.

Plastic caissons

Lightweight, easy to install, long-lasting, not afraid of rust, completely sealed. Plastic has good heat-shielding performance, and therefore is often used without additional insulation, it does not need to be protected from groundwater. One of the most inexpensive options: the price is much lower than that of a metal caisson for a well. The cost of budget mini-structures made of polymers starts at 1000 rubles, and the cheapest metal tank costs about 9000 rubles.

The plastic caisson for the well consists of two parts: above-caisson and caisson. The first can be of a smaller section. A distinctive feature of the structures is a crimp sleeve, which ensures the tightness of the junction of the casing string with the caisson tank. The set may include special pipes used for laying wires, pipes for water and other elements to facilitate operation.

Polymer products have two drawbacks: susceptibility to deformation and buoyancy. They should be mounted on a specially equipped concrete pad.

Polymer sandy options are similar in quality to plastic ones, but they are more resistant to deformation. The rigidity required for the operation of the caisson is obtained by adding sand to the polymer matrix.

Installation of ready-made structures or DIY manufacturing

It is easiest to create a brick caisson with your own hands, since working with concrete rings will require the involvement of special equipment. Before starting work, it is worth making a drawing in order to visually represent the future structure. For the construction of the caisson, a concrete base is prepared, on which brick walls are subsequently erected, and an overlap with a hatch is installed on them.

There are two options for arranging such structures: with and without backfill. In the first, a pit is dug, larger in size than the future structure. When the walls of the caisson tank are erected and dry well, the voids are covered with earth. In the second method, a pit is prepared exactly according to the size of the future structure. Bricks are laid out on the wall, however, there is no guarantee that there will be no empty spaces behind them. The backfill method requires a lot of labor, but the container comes out of higher quality and lasts longer.

The structure is being erected to a height of about two meters so that it is convenient to work, install equipment and deepen the container below the freezing point.

As for the placement of the finished product, it will also require a pit, which is larger than the caisson by at least 30 cm.This contributes to a more accurate installation with correcting the coincidence of the well pipe and the sleeve under it. It also makes it possible to insulate the walls or strengthen, which is necessary for a plastic container.

Installation of a metal container is carried out in the following sequence:

- Before installation, the outer part is covered with waterproofing. It is primed and insulated inside.

- A base is created - a sand cushion with a concrete slab on top.

- The well pipe is cut to size.

- A caisson is placed above the pit on the bars or channels and is adjusted until the casing and liner match.

- A complete installation of the caisson tank is being carried out.

- Trenches are being dug for water supply.

- Bushings are welded into the walls of the caisson tank for the entrances. Fitting parts are screwed into them with output to the required consumers.

At the end, additional thermal insulation and waterproofing is carried out, the container is covered with earth.

Installing a plastic structure is very similar to installing a metal caisson. The difference is that when sealing the connection of the well pipe with the sleeve, not welding, but PVC glue is needed. Pipes are passed through walls not through threaded bushings, but through special couplings, closed with sealing plugs.

An important feature of plastic is that there is no need for insulation from water and cold, but an indispensable protection against crushing by soil is required. The void between the walls of the pit and the container is poured with concrete. Also, the plastic container must be fixed with anchors on a concrete base.

Maintenance and operation

A properly assembled caisson rarely needs maintenance. In concrete and brick chambers, additional insulation from the inside or waterproofing may be required.

For thermal protection of the inner walls, instead of traditional polystyrene and polystyrene foam, polyethylene foam can be used - there is no earth pressure on it.

Due to the presence of welded seams, metal devices are most often subject to loss of tightness - in this case, they are welded from the inside with special expensive electrodes designed for welding in an environment with high humidity.

Caissons are an element necessary for high-quality well construction. When choosing the right option, take into account the terrain, wells and financial capabilities.