The advantage of fan coil units is manifested in large areas - in office centers, retail premises. The system allows, depending on the season, to heat or cool the air. If a fan coil unit operates all year round, sooner or later breakdowns occur associated with the key components of the system: a heat exchanger, a fan or a cleaning filter. In this case, the system stops functioning.

In order for the fan coil to work correctly, you need to regularly carry out routine maintenance work, cleaning filters and air ducts, and replacing parts. This is done by specialized licensed firms. You can independently carry out maintenance of fan coil units if you have experience in such work.

Fan coil unit

Fan coil units work like a conventional wall-mounted air conditioner. A distinctive feature is a liquid that acts as a refrigerant: in split systems it is freon, in a fan coil unit - water or antifreeze. From the room where the fan coil is located, air is directed to the heat exchanger. Cooling or heating takes place there. The pressure in the system contributes to a constant supply of fresh air from the street.

A chiller is a refrigeration unit to which a fan coil is connected. It is also connected to a boiler or boiler.

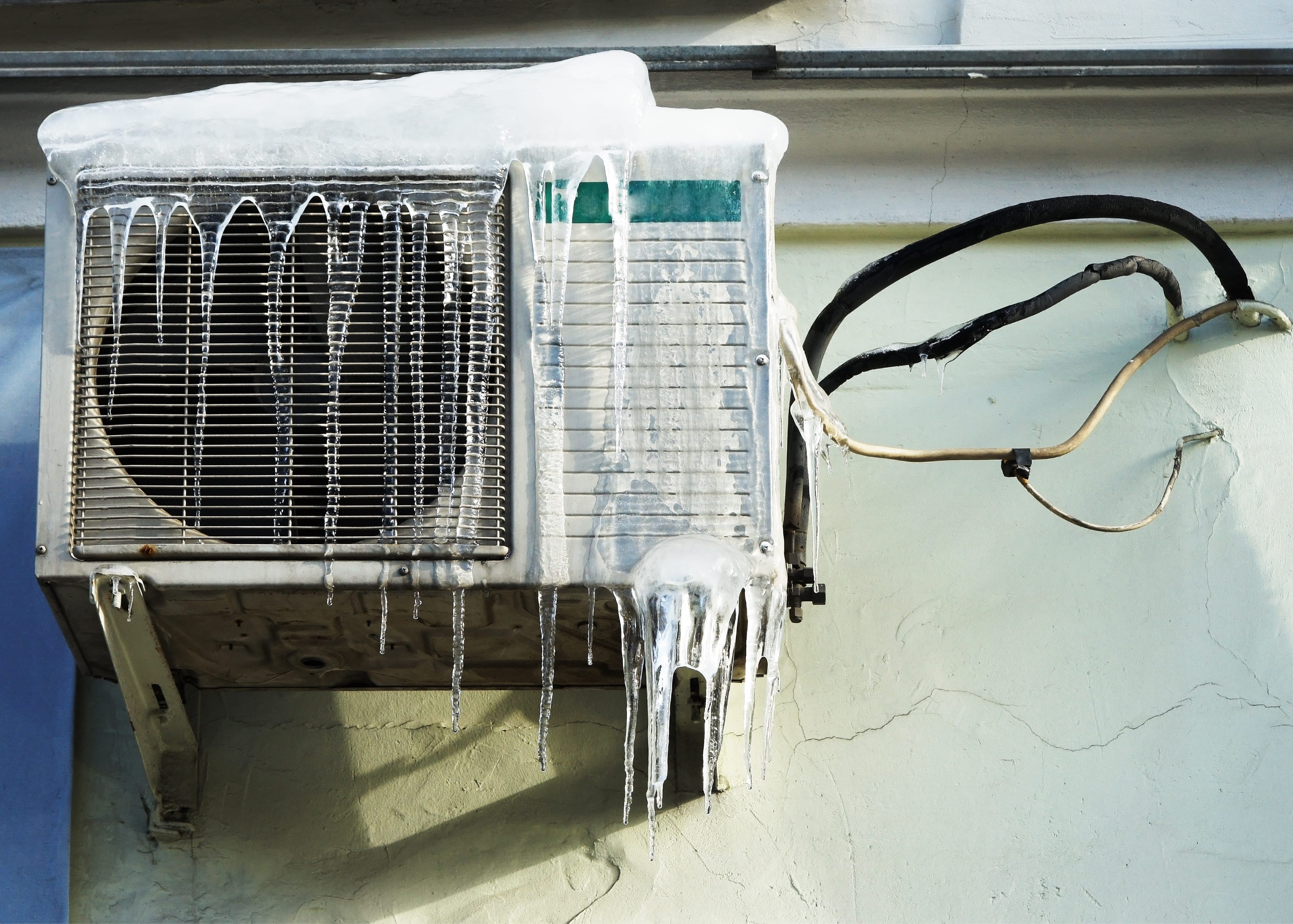

In air conditioning mode, condensing liquid accumulates on the heat exchanger, which can interfere with the normal operation of the entire system and even damage it.

Fan coil units are distinguished by types:

- built-in and free-standing floor-standing;

- vertically arranged and horizontal;

- in the case and frameless;

- two or four-pipe.

Each design requires a professional approach and adherence to service rules.

Typical malfunctions

Repair of fan coil units is necessary in case of the following problems:

- Dirty filters, preventing the system from operating at full capacity. Cleaning the fan coil units and air conditioner shafts is a mandatory activity that takes place twice a year before the heating and cooling season. The first sign is an unpleasant odor, when it appears, they call the masters to diagnose the system. The malfunction does not require dismantling, the work is carried out on site.

- Wear of parts. Constant intensive work leads to premature equipment failure. Defective air conditioner parts break faster. Depending on the location of the faulty structure, problems are eliminated on site or at a service.

- High humidity and mold. The first sign is that condensation begins to accumulate inside the room, the windows fog up. Cleaning and disinfection of the ventilation shaft is required. Fluid leaks can cause similar fan coil malfunctions. The dirt that accumulates in the heat exchanger is a breeding ground for microorganisms.

- Increased vibration, extraneous sounds during work.

- No cooling or heating while the system is running.

In order not to bring the equipment to obvious errors, it is necessary to inspect for potential problems long before they appear.

Renovation work

Recovery measures are carried out in case of serious equipment breakdowns.

Compressor does not work

Actions depending on the breakdown:

- Switch defective: find cause or replace.

- Fuse blown: replace.

- Refrigerant leaks: locate the leak, seal and top up.

- There is a lot of fluid in the system: measure the pressure and remove the excess.

- Gas appears in the fan coil unit: release and restart the system.

- Air inlet obstructions: inspect fan for dirt.

- The compressor is overheating. If there are problems with the bearings, it must be replaced. Other reasons: frequent activation, insufficient lubricant.

- Electrical problems - high or too low voltage: fix.

The device must be inspected by several specialists. Do-it-yourself fan coil maintenance can lead to complete failure of expensive equipment due to incompetent intervention in the repair process.

Incorrect installation and selection of the installation site leads to frequent repairs and maintenance of the chiller.

The chiller is a unit weighing from 400 to 5000 kg, depending on the capacity, so the team is forced to carry out maintenance on site. The price in this case is much lower, because dismantling and transportation are more expensive than the repair itself.

Fan breakage

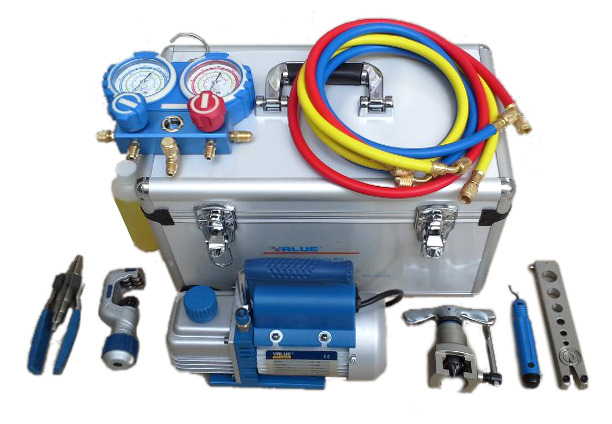

Repair technical work in case of fan breakdown:

- replacement;

- cleaning the impeller;

- centering, if the wings cling to adjacent parts;

- repair of the electrical component of the fan.

The prices for the repair of the fan are determined by the degree of breakdown and the need for transportation to the service.

Repair of cassette and channel fan coil units

Cassette fan coil units require periodic replacement of curtains and electric drives, adjusting the direction of the air flow. Contamination on the cassette is eliminated twice a year to ensure free passage of air to the heat exchanger.

It will be more expensive to repair a ducted fan coil unit, since the system is hidden behind a false ceiling. The work requires the dismantling of the ceiling structure to provide access to the units located in the room. The process takes more time and requires additional tools, as well as restoring the integrity of the ceiling after inspection or repair.

Mandatory maintenance measures: work schedule

The list of mandatory technical work includes:

- visual inspection for mechanical defects and damage to units;

- checking all operating modes of the remote control;

- cleaning filters and heat exchanger, as well as fan impellers and curtains;

- measurement of the air temperature at the inlet and outlet of the fan coil;

- measurements of fluid pressure in the system;

- drainage system check;

- measurements of currents in the engine;

- inspection of electrical wiring for wear.

After carrying out preventive measures, specialists draw up an act in two copies, one remains with the contractor, the other with the customer of the services.

It is not recommended to entrust the maintenance of expensive systems to incompetent persons. Qualified teams of workers will quickly fix problems. In case of repeated failures, you can ask for help on the basis of a drawn up certificate of work performed.